Introduction

As the global furniture market continues evolving, 2025 is shaping up to be a pivotal year for the the rattan manufacturing industry. Trends in design innovation, sustainability practices, and export expansion are reshaping the way rattan products are created, marketed, and delivered. Indonesia, with its abundant rattan supply and artisanal heritage, is well-positioned to lead these shifts.

Here’s a deep dive into the major trends that will define rattan manufacturing in 2025 and beyond.

1. Design Trends: From Minimalism to Modular & Multifunctional

a. Minimalist and Organic Aesthetics

The minimalist, “less is more” aesthetic continues to dominate. Designers are favoring clean lines, neutral palettes, and organic forms that highlight the natural texture of rattan. This aligns with global interior trends toward calm, breezy, grounded spaces.

Consumers are also drawn to the imperfections and irregularities of handmade rattan — viewing them as evidence of authenticity rather than flaws.

b. Modular & Multifunctional Furniture

With urban living spaces becoming smaller, modular rattan furniture is gaining traction. Think stackable chairs, interlocking loungers, or convertible pieces that can shift from indoor to balcony use.

These flexible designs help brands reach customers in dense cities and serve dual-use settings (indoor/outdoor).

Some Indonesian manufacturers are already prototyping modular rattan components to allow easier packing and shipping.

c. Mixed Materials & Hybrid Designs

Combining rattan with materials like teak wood, recycled aluminum, or blackened steel is a growing trend. The contrast between natural rattan weave and sleek, modern frames creates a contemporary balance.

Teak rattan furniture is especially popular because teak’s durability and weather resistance complement rattan’s weaving artistry. indonesiarattan.com+1

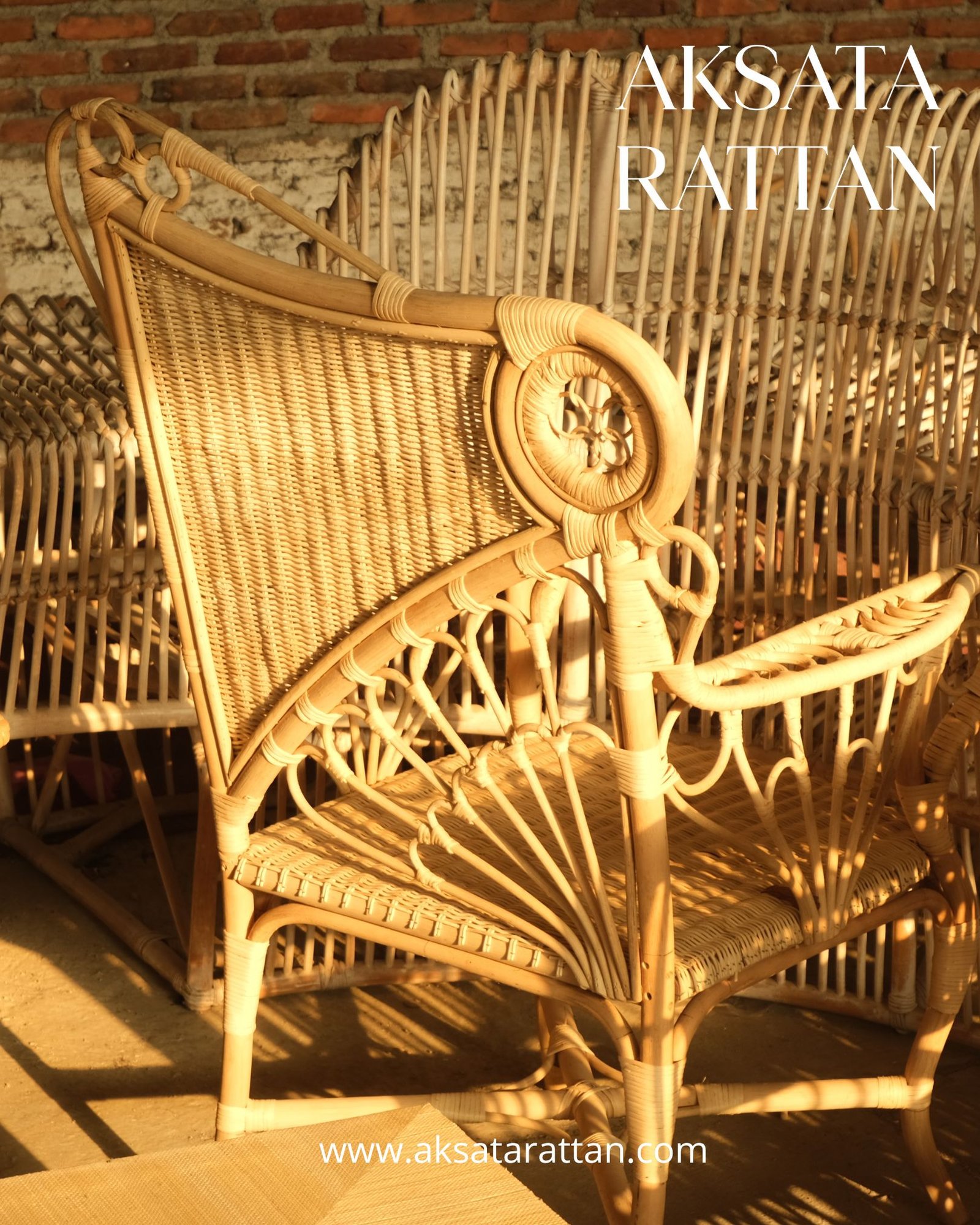

d. Sculptural & Statement Pieces

Beyond chairs and tables, rattan is being used as art — sculptural partitions, large-scale weaving installations, and dramatic pendant lights. These pieces serve as focal points in interiors and elevate rattan beyond “just furniture.”

2. Sustainability & Ethical Manufacturing

a. Traceability & Certification in Raw Material Sourcing

Sustainability is no longer optional — it’s expected. Manufacturers are increasingly demanding certification like SVLK (Indonesia’s Timber Legality Verification System) and FSC to validate that raw rattan is harvested legally and responsibly.

This traceability is becoming a requirement for many international buyers.

b. Regenerative Harvesting & Forest Stewardship

Rather than just “sustainable” harvesting (take-care not to overharvest), some rattan producers are moving toward regenerative models — actively restoring and managing forests so rattan yields increase over time rather than decline.

These practices help secure future supply and reinforce environmental branding.

c. Low-VOC, Water-Based Coatings and Eco-Finishes

The finishes used on rattan products are evolving. Water-based stains, natural oils, and low-VOC (volatile organic compound) clear coats reduce environmental impact and satisfy stricter import regulations in regions like the EU and North America.

d. Waste Minimization & Circularity

Rattan offcuts, shavings, and failed pieces aren’t being discarded. Many factories now reuse them in small decorative items, composite boards, or even as biomass fuel in kilns. This minimizes waste and maximizes value per input.

e. Social Responsibility & Artisanal Empowerment

Buyers are looking deeper — beyond materials — into how artisans are treated. Fair wages, safe working conditions, and community-benefiting initiatives add to the appeal.

Manufacturers who transparently show their social impact have a competitive advantage.

3. Export Growth: Market Dynamics & Challenges

a. Market Expansion & Forecasts

- The Indonesian rattan furniture market is forecast to grow ~11.57% in 2025, building to ~14% by 2029. 6Wresearch

- Globally, the rattan furniture market is expected to reach ~$0.96 billion in 2025 and grow toward ~$1.22 billion by 2030, at a CAGR of ~5%+ Mordor Intelligence

These projections show that while rattan is still a niche compared to wood furniture, it is one of the faster-growing segments — especially in the “green / sustainable” category.

b. Domestic Value-Addition & Export Strategy

Indonesia has policies disincentivizing raw rattan exports, encouraging domestic processing and export of finished goods. Business Indonesia

Thus, manufacturers that can move up the value chain — from cane to finished furniture — will gain more margins and control.

c. Diversification of Export Destinations

Traditionally, exports went to the U.S., Europe, and Australia. In 2025 and beyond, demand is also rising in Middle East, South Asia, and Latin America — markets less saturated and with growing interest in sustainable design.

d. Supply Chain & Raw Material Risks

Challenges remain. Some of the biggest are:

- Raw material scarcity due to deforestation or aging rattan stands

- Rising labor and logistics costs (labor shortages, shipping delays)

- Import barriers — stricter environmental, fumigation, or legality rules in importing countries

To mitigate, manufacturers must invest in vertical integration, strategic partnerships with rattan plantations, and automation in non-artisanal stages.

e. Digital & E-Commerce Export Channels

More Indonesian rattan makers are selling directly via platforms like Alibaba, Etsy, and B2B portals. This cuts out middlemen, improves margins, and opens access to niche markets.

Virtual product demos, augmented reality previews, and better photography are helping smaller manufacturers reach global buyers more effectively.

4. What This Means for Your Business (Aksata Funricraft & Buyers)

- Differentiation through design will be essential — your collections should reflect the trends above (modular, hybrid, statement) while still showing your signature craftsmanship.

- Sustainability must be integral, not just a marketing line. Certifications, fully traceable supply chains, and circular practices will be expected by serious buyers.

- Export-readiness requires more than good design — you must master packaging, logistics, compliance, and after-sales support.

- Scale with care: invest in automation where possible (e.g. cutting, drying, quality inspection), while preserving artisanal integrity in weaving and finishing.

- Brand storytelling will matter more than ever — consumers want to know who made it, where the rattan grew, and what environmental or social impact the piece had.

Conclusion

In 2025, the rattan manufacturing industry is rising to meet higher expectations. The convergence of innovative design, deep sustainability commitments, and export expansion is shaping a new generation of rattan businesses — not just factories, but brands with purpose.